Subtotal تومان0

Industrial milk powder is a versatile and essential ingredient, widely used in food production for its nutritional value, long shelf life, and adaptability to various applications.

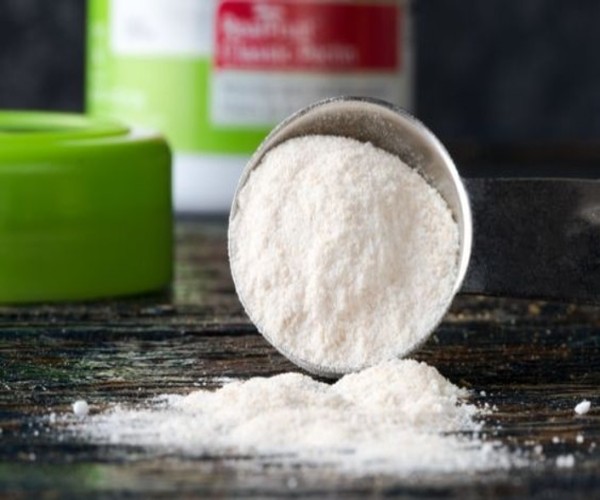

Industrial milk powder

Industrial powdered milk is one of the most widely used products in the food industry, which is obtained by drying fresh milk. This product is used in the production of many food products due to its long shelf life, low weight and easy transportation. Industrial powdered milk is mainly used in the production of dairy products, sweets, bread, chocolate, and various sauces.

One of the main advantages of milk powder is to preserve the nutritional properties of fresh milk; Including protein, vitamins and minerals. Also, this product can easily replace fresh milk in various production processes due to its ability to dissolve quickly in water. Food and pharmaceutical industries look at industrial milk powder as a very important raw material, because its quality control helps to maintain the final quality of the products. Large milk powder manufacturers use strict hygiene standards and advanced processes to ensure product quality.

1-Production process:

2- Types of Industrial Milk Powder

3- Compositions:

4- Industrial applications:

5- Advantages and features:

6- Standards and quality:

"We have unique experience and expertise in providing quality industrial powdered milk from the best global manufacturers, to provide you with a reliable product with high standards."

Industrial powdered milk is one of the best products in the food industry due to its production from high quality milk, advanced processing and in accordance with international standards, maintaining nutritional values and long shelf life. These features have made it popular in various domestic industries and international markets.

Emphasizing quality and trust, Atra always strives to meet the needs of customers and provide a unique experience of quality products. We attach great importance to customer satisfaction and are always by our customers' side by using the best raw materials and premium after-sales service.

Adhering to complete transparency in the contracts, Atra clearly specifies all the conditions, rights and obligations in order to gain the confidence and trust of the customers and prevent any ambiguity and dispute.